FAQ and troubleshooting

What are the possible statuses for an order?

Based on the actions you perform such as creating an order, submitting an order, or updating an order, an order type can have one of the following statuses:

Created: A purchase order is in Created status when you save the Purchase Order without submitting it to the vendor.

Note

In the Created status, you can continue to add products that you want to procure.

Example: Let’s say you are short of 50 bottles of Citrus Face Pack and 25 bottles of Peach Face Scrub. You create a purchase order and add 50 bottles of Citrus Face Pack and save the order. The order is created and the status of the order changes to Created. Later, you can open the same purchase order and add 25 bottles of Peach Face Scrub.

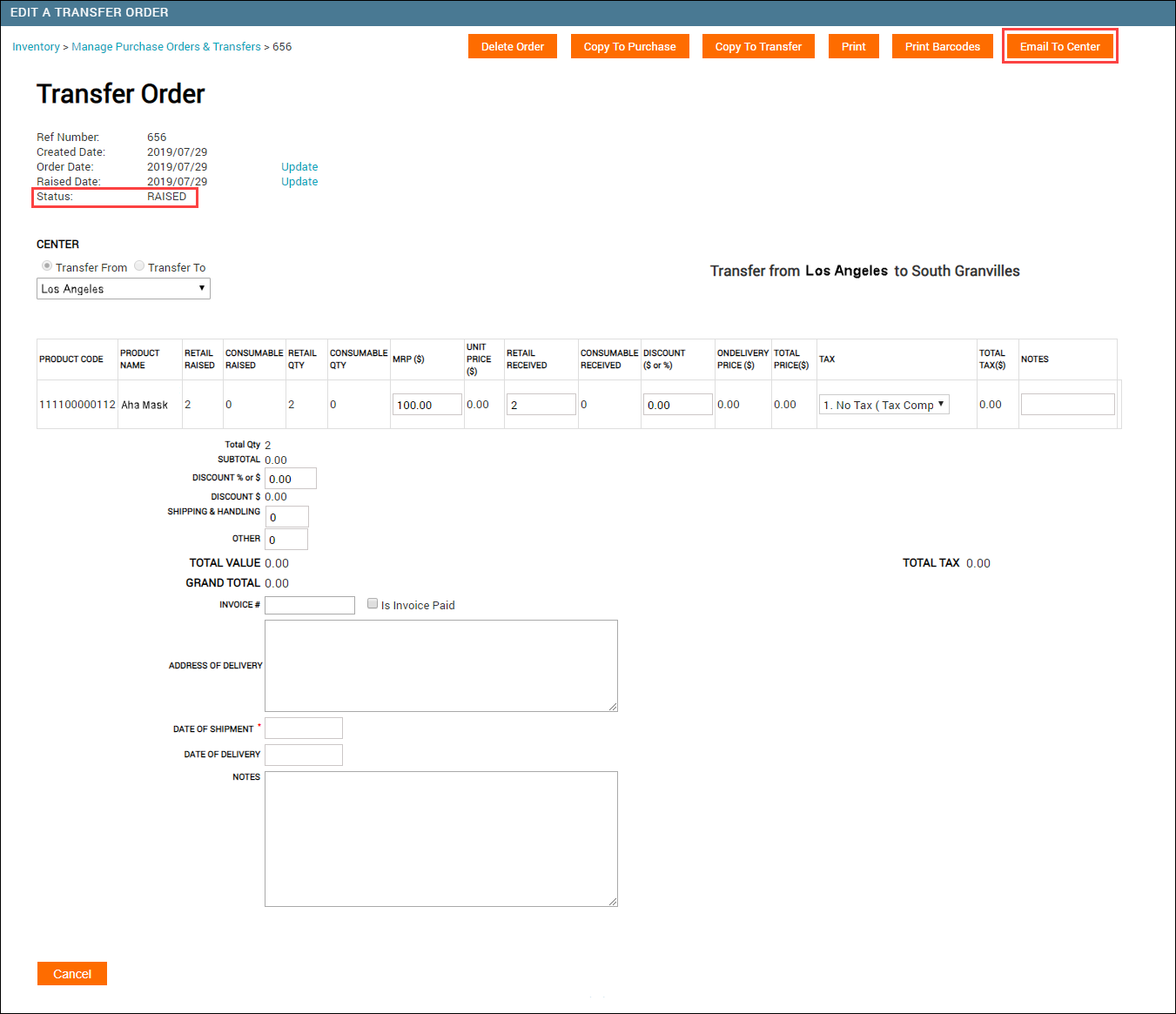

Raised: A purchase order is in Raised status when you save and submit the Purchase Order to vendors. In the Raised status, you can mark the purchase order as partially delivered or fully delivered based on the quantity you receive from the vendor.

Note

For every partial or full delivery you mark, Zenoti automatically updates the current stock.

Example: Let’s say that you are short of 50 bottles of Citrus Face Pack. You create and submit the purchase order to the vendor. The order is submitted and the status of the order changes to Raised.

Updated: A purchase order is in Updated status when you accept partial delivery of an order, but you click Save instead of marking it as Partially Delivered.

Example: Let’s say that you have raised a purchase order requesting 50 Papaya chapsticks for retail use. However, for some reason, your vendor was able to deliver only 30 chapsticks. Therefore, you update retail portion of purchase order with the received quantity and just save it. The order is updated and the status of the order changes to Updated.

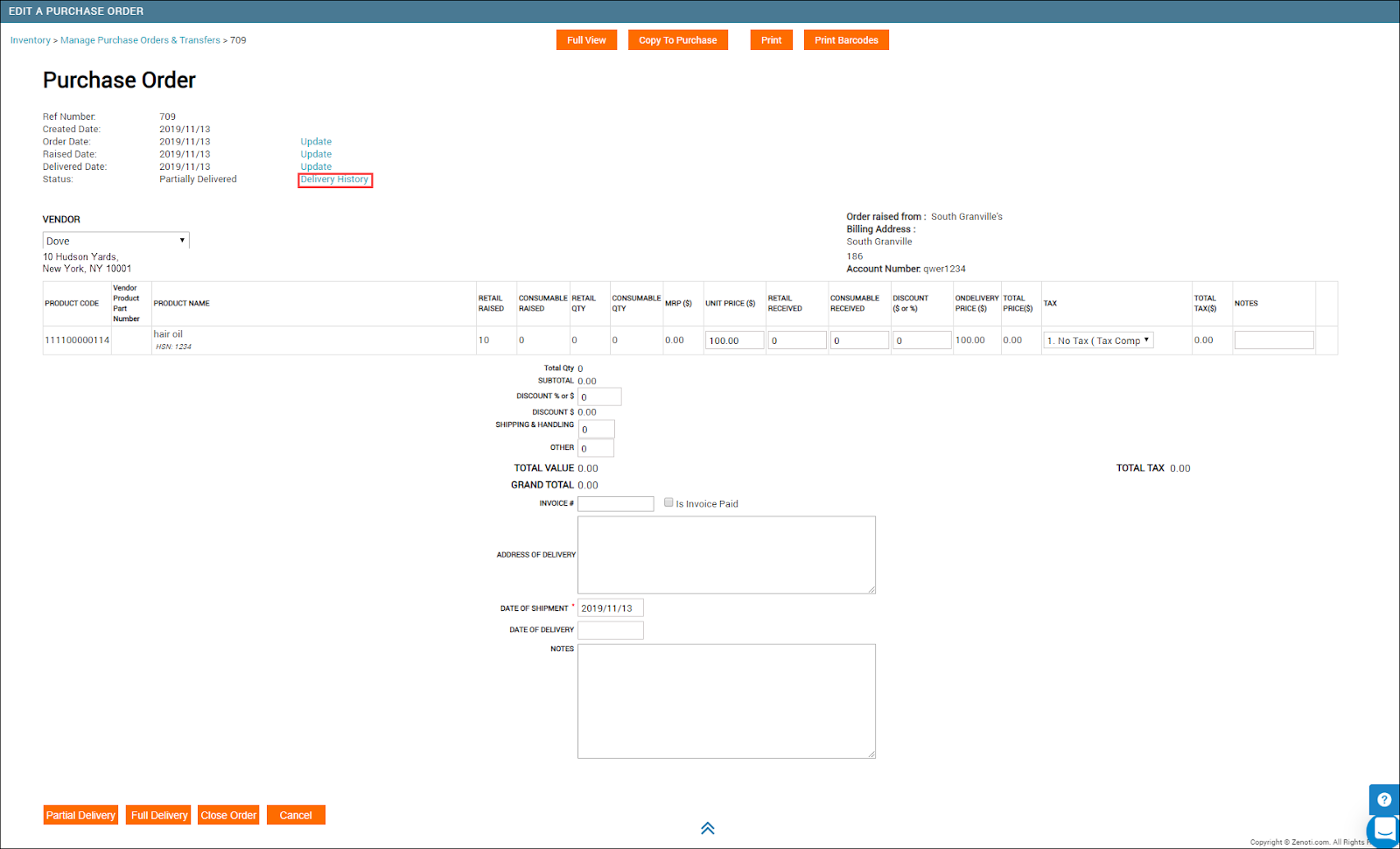

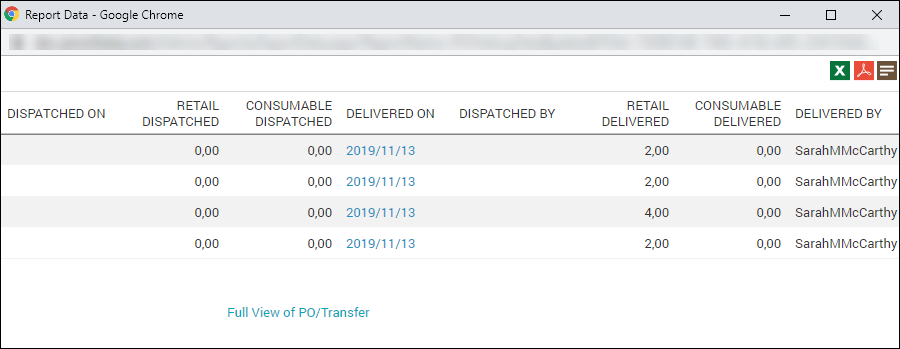

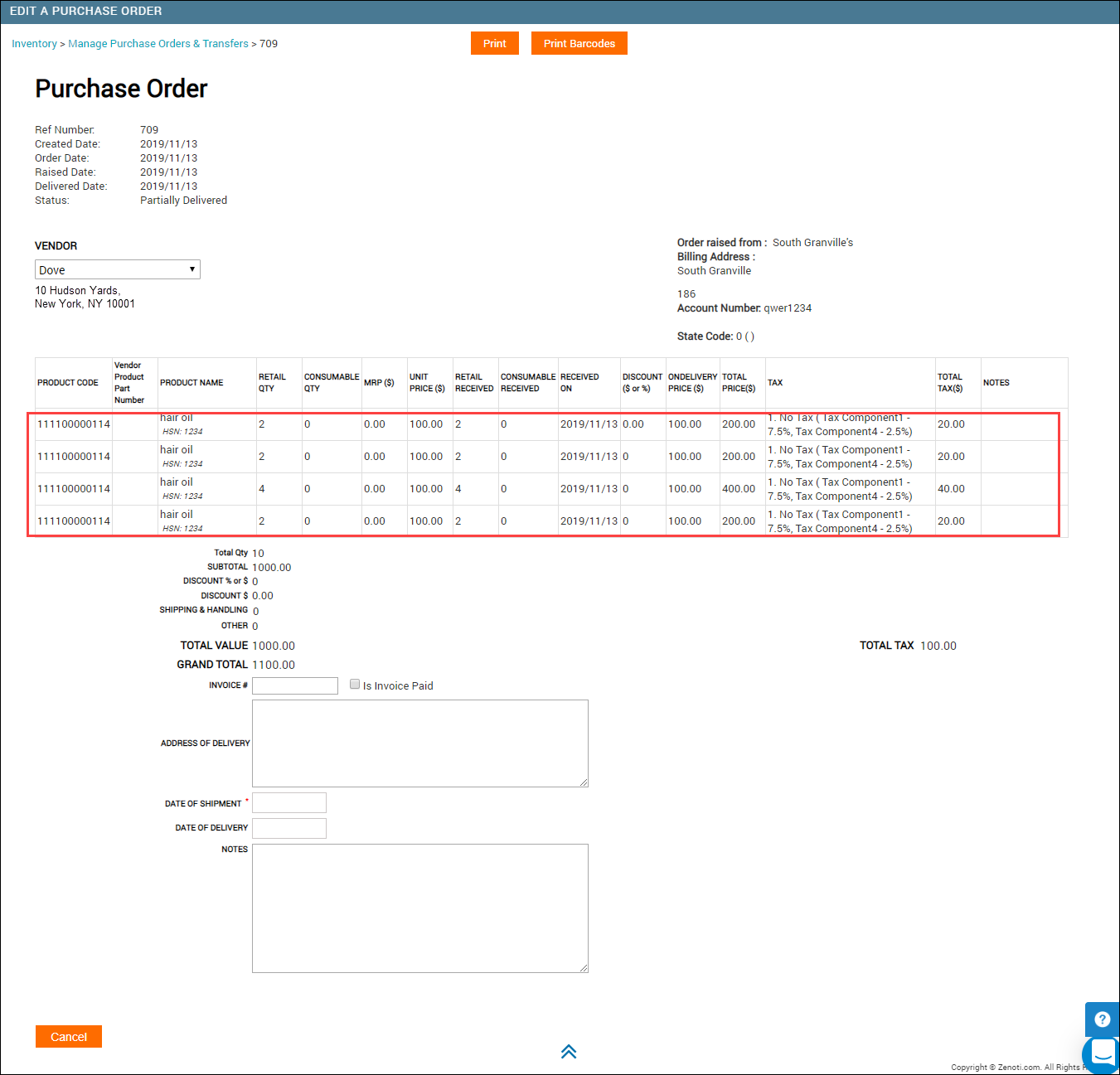

Partially Delivered: A purchase order is in Partially Delivered status when you accept partial delivery of an order in two or more shipments.

Example: Let’s say that you have raised a purchase order requesting 50 Papaya chapsticks for retail use. However, for some reason, your vendor was able to deliver only 30 chapsticks. Therefore, you update retail portion of purchase order with the received quantity and mark it as Partially Delivered. The order is updated and the status of the order changes to Partially Delivered.

Delivered: A purchase order is in Delivered status when you accept full delivery of the requested products.

Example: Let’s say that you have raised a purchase order requesting 30 Mint chapsticks for retail use. Your vendor delivered total stock as requested. Therefore, you update the retail portion of purchase order with the received quantity and mark it as Fully Delivered. The order is updated and the status of the order changes to Delivered.

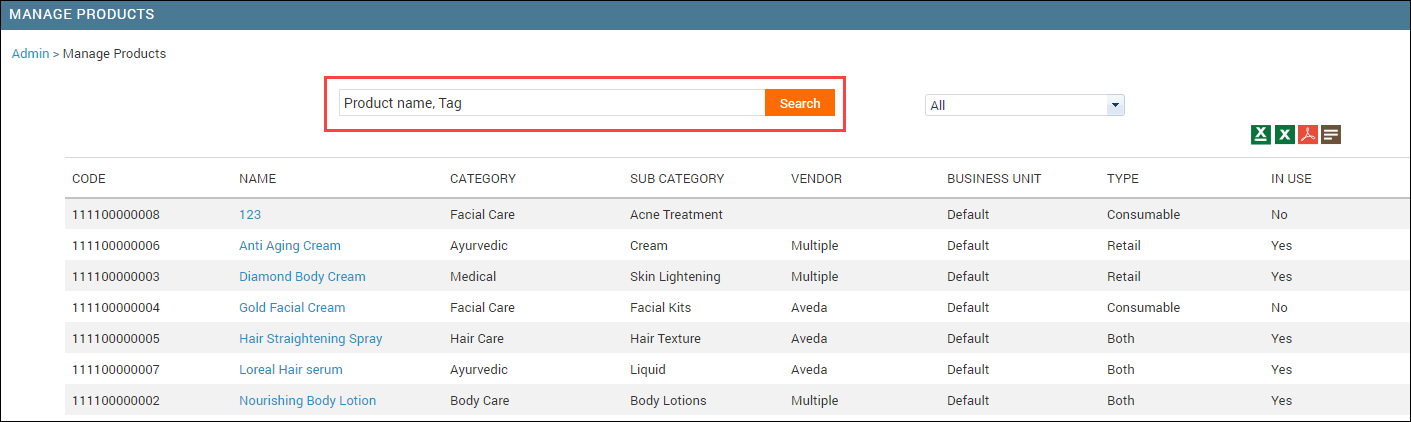

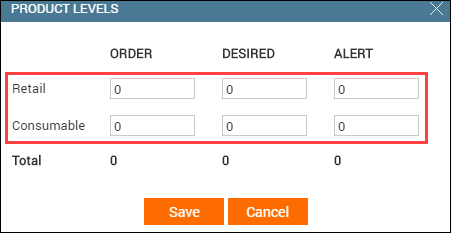

How can I manage and differentiate consumable and retail products in Zenoti?

Zenoti provides robust tools for categorizing and managing inventory, allowing businesses to track and differentiate between products used internally (consumables) and those sold to customers (retail products). This guide offers an overview, system behaviors, configuration instructions, and operational considerations for handling these product types.

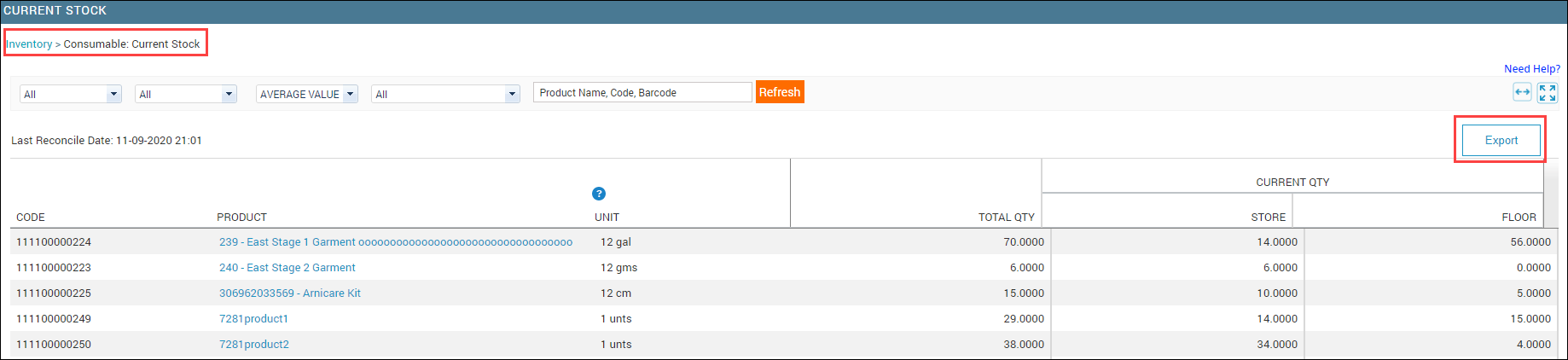

Understanding consumable and retail product types

Consumable products: Items intended for internal use during services, such as shampoo used before a haircut or massage oils. These are not sold directly to customers.

Retail products: Items sold directly to customers, intended for their personal use outside the business environment.

System behavior and dual-category products

In Zenoti, products can be categorized as both consumable and retail. This dual classification has implications for how products are tracked and audited:

Products marked as both retail and consumable appear in both the retail audit and consumable audit sections of the system, with their values displayed accordingly. For instance, consumable values show up in the consumable audit screen, while retail values appear in the retail audit section.

Items may appear in the retail audit section because of this dual-classification status, even if they are consumables.

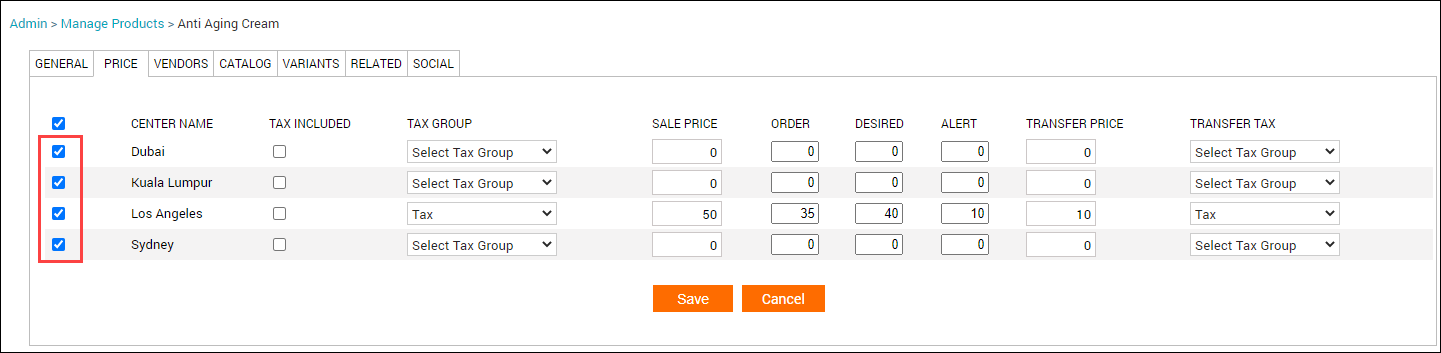

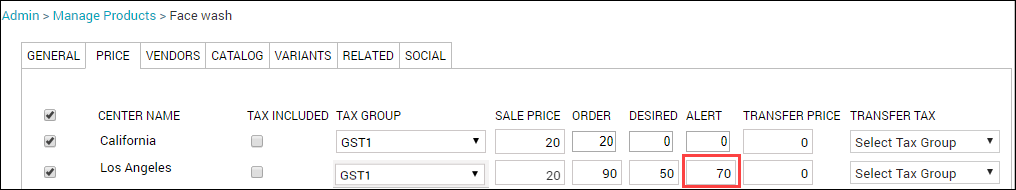

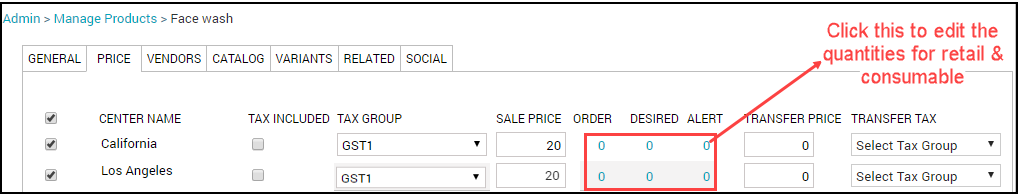

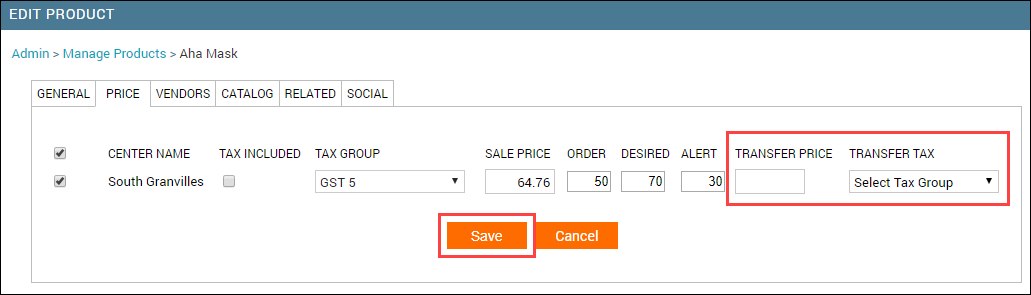

Configuring products in Zenoti

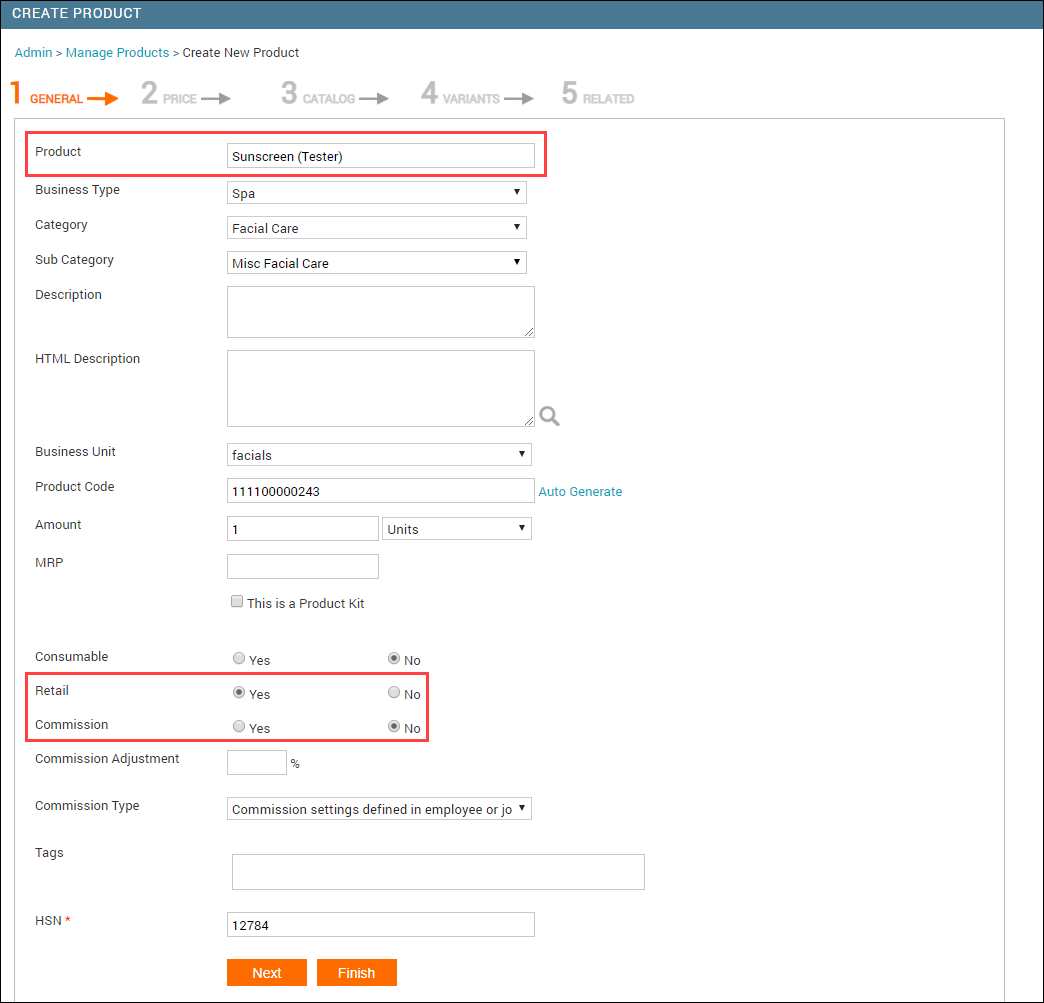

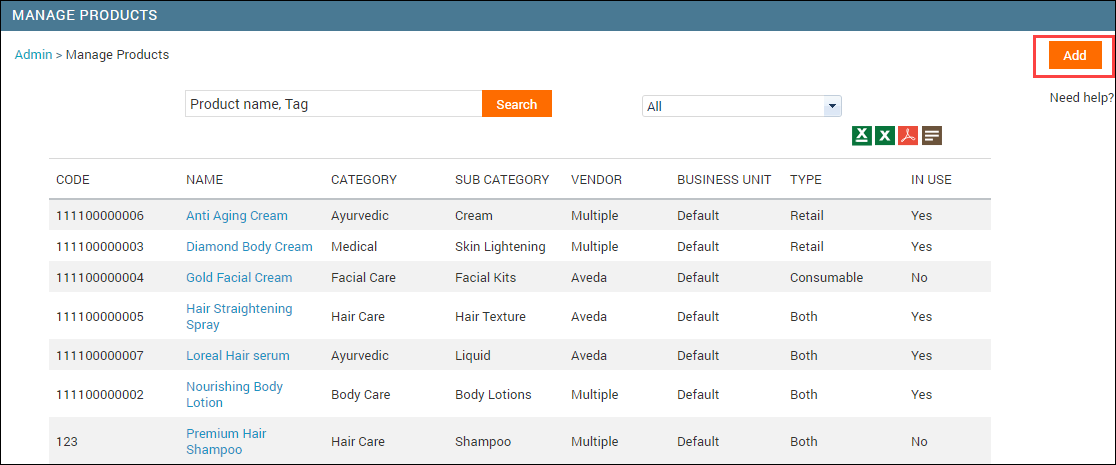

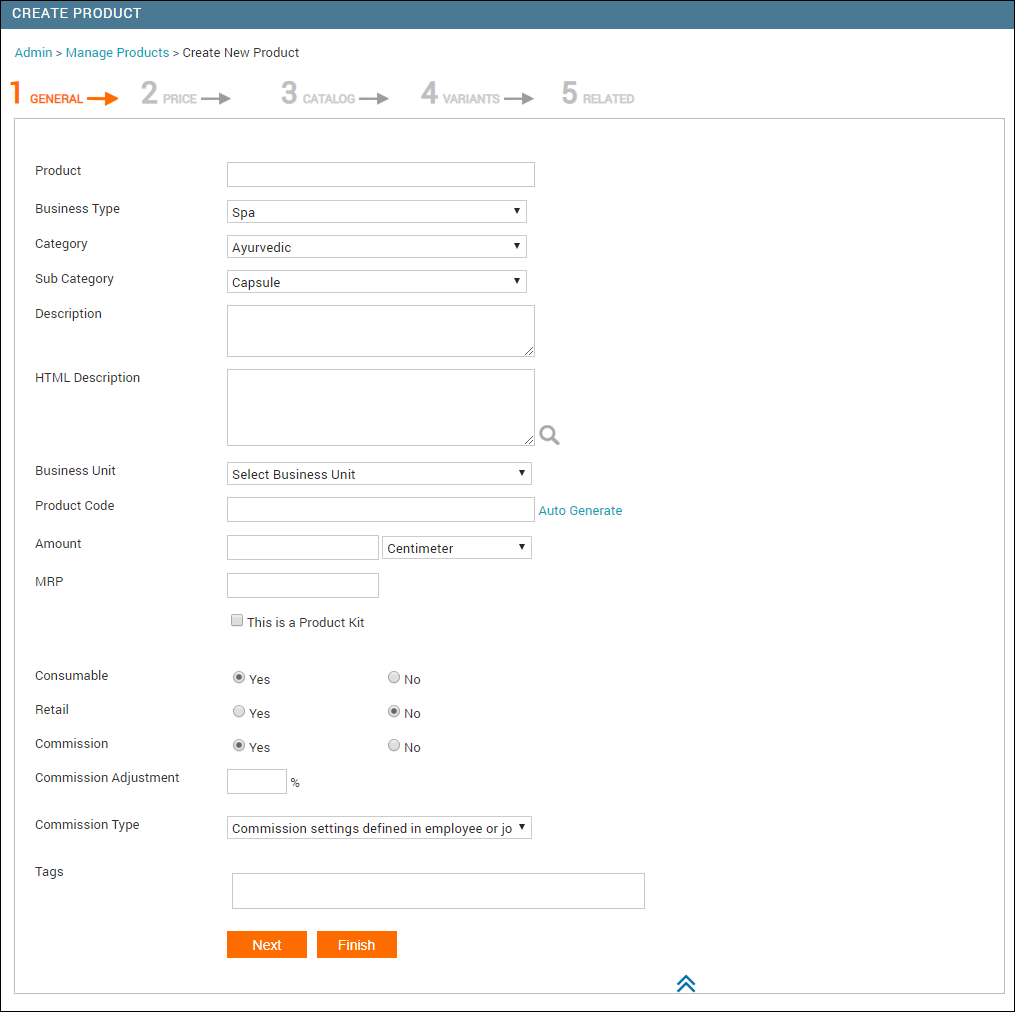

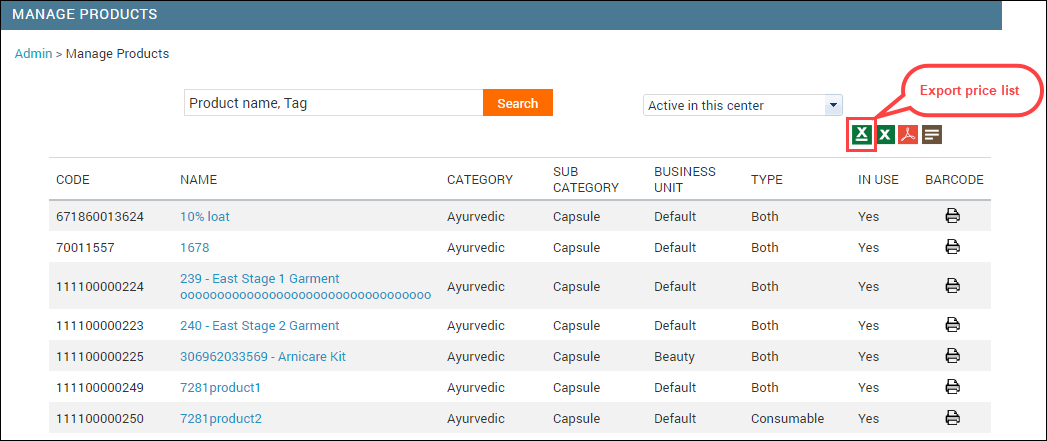

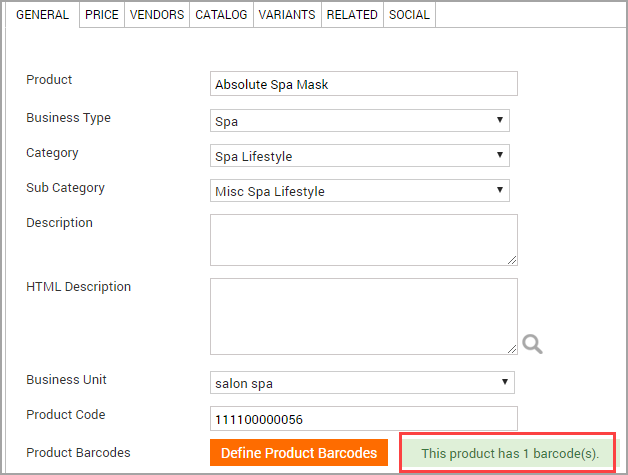

You can classify a product as consumable, retail, or both by following these steps in Zenoti:

At the organization level, navigate to Master Data > Product > General Tab.

Scroll down to find the checkboxes labeled Retail and Consumable.

Select the appropriate options for the product.

Choose Retail to make the product available for sale.

Choose Consumable for products to be tracked as used internally.

Select both options if the product serves both purposes.

Consumable products must have a non-zero quantity associated with the service to ensure proper usage tracking. Retail products can typically be linked to the POS (Point of Sale) without requiring usage tracking. If needed as part of a service, ensure the following configurations:

Disable the Allow product consumption entry in appointment book option. Associate the product under the Products tab within the service settings.

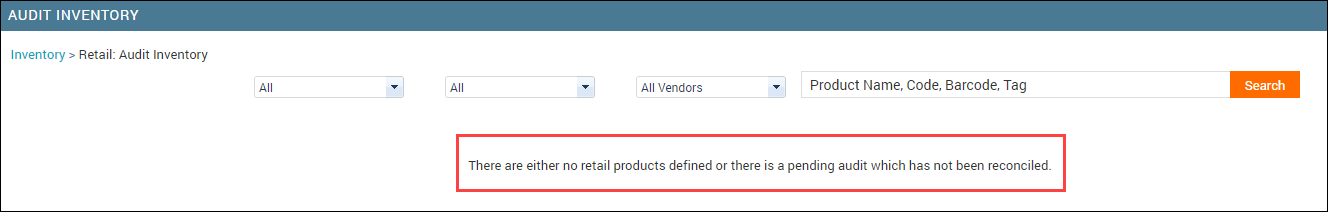

How can I manage inventory discrepancies and write off retail products in Zenoti?

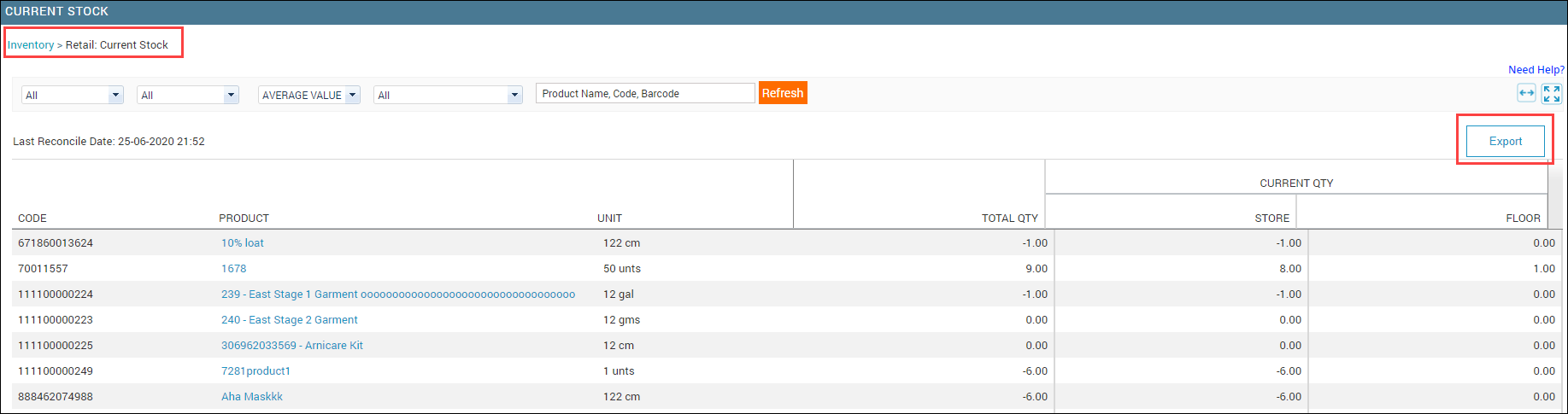

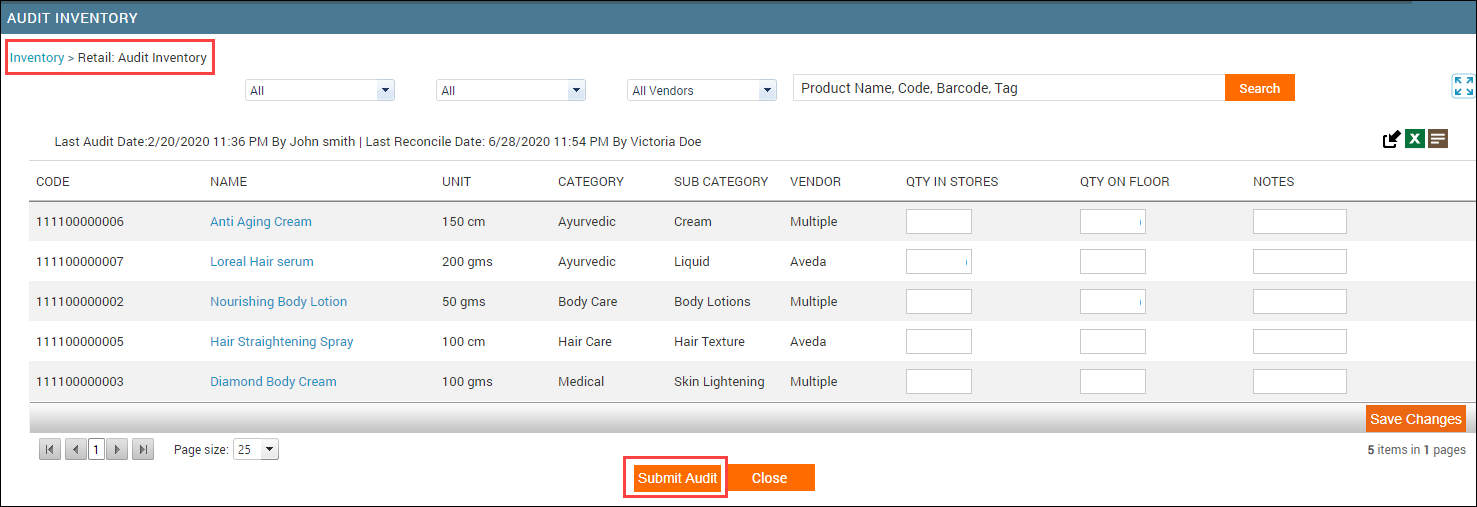

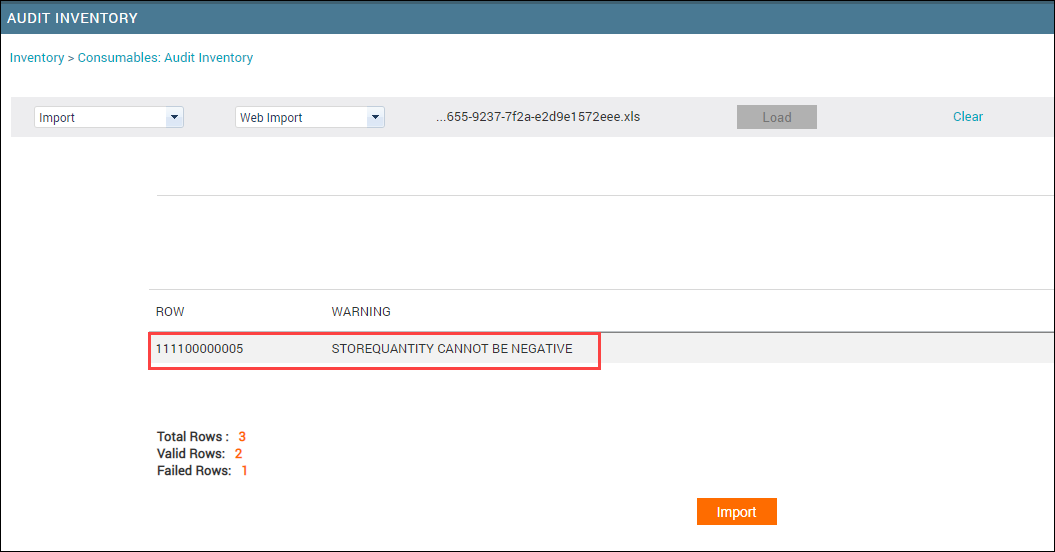

Proper inventory management in Zenoti ensures product accuracy, prevents stock discrepancies, and supports smooth daily operations. Auditing helps verify actual stock against recorded quantities and maintain data accuracy.

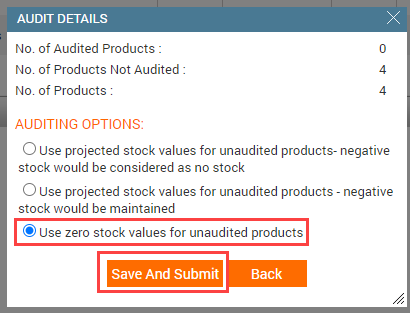

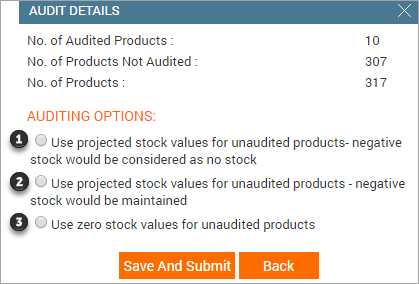

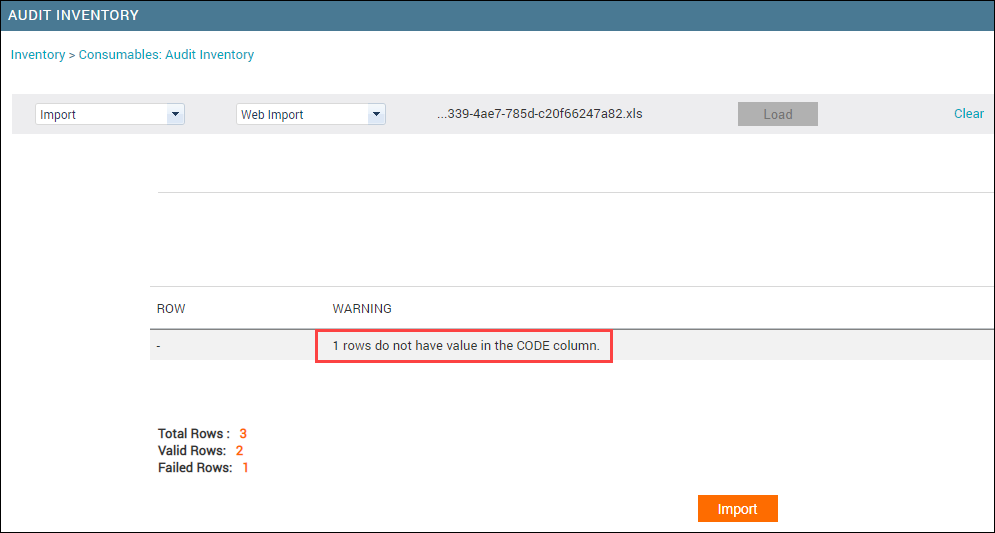

At the center level, navigate to Inventory > Audit .

Enter the correct on-hand quantities for a product.

Select Submit only above products.

Click Submit Audit.

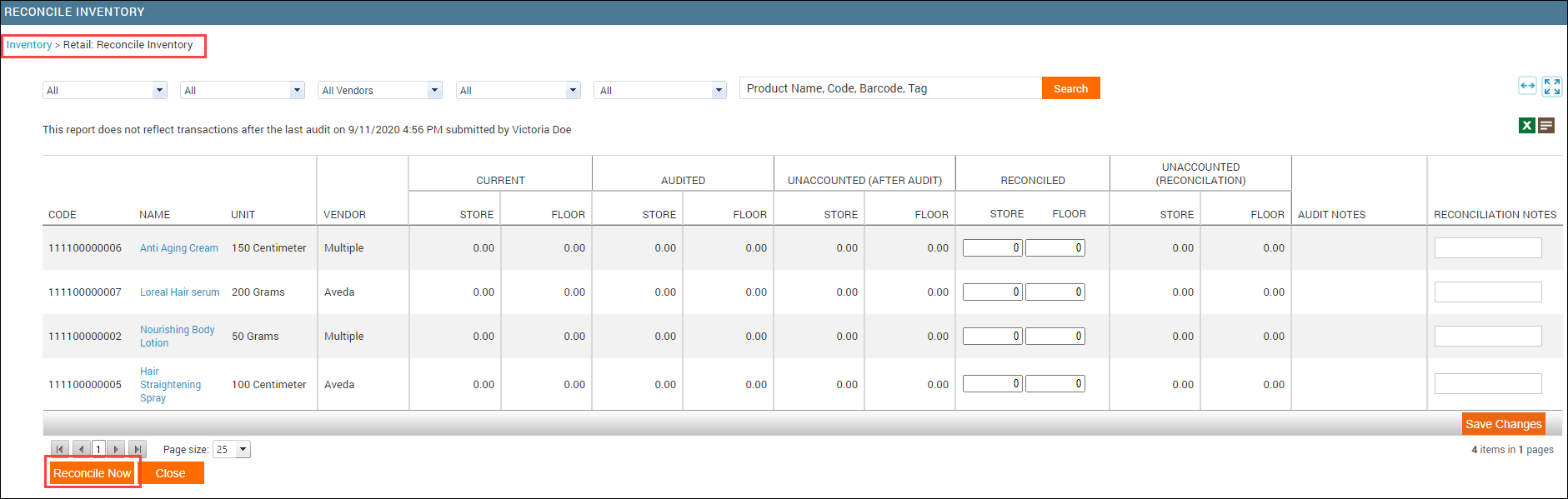

Reconciliation updates Zenoti to match physical stock levels.

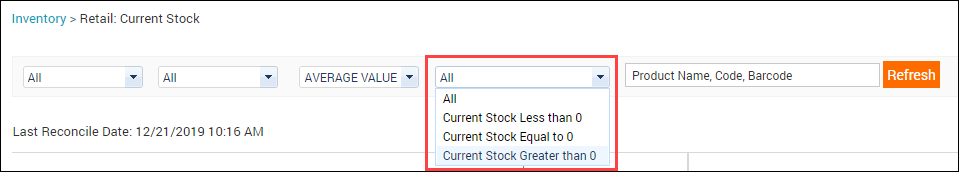

At the center level, navigate to Inventory > Retail/Consumable > Reconcile.

Enter the reconciled on-hand quantity.

Click Submit Reconcile.

Negative stock occurs when received stock doesn’t fully offset existing negative quantities.

Conduct a physical stock check to confirm actual quantities.

Update Zenoti using Audit and Reconcile.

Ensure any saved audits are submitted to prevent incomplete updates.

Discarding or writing off removes unusable products.

Update the quantity using Audit and Reconciliation.

Enter clear Notes explaining the reason for discarding (for example, Discarded 3 units of Herbal Silky Shampoo due to damaged bottles).

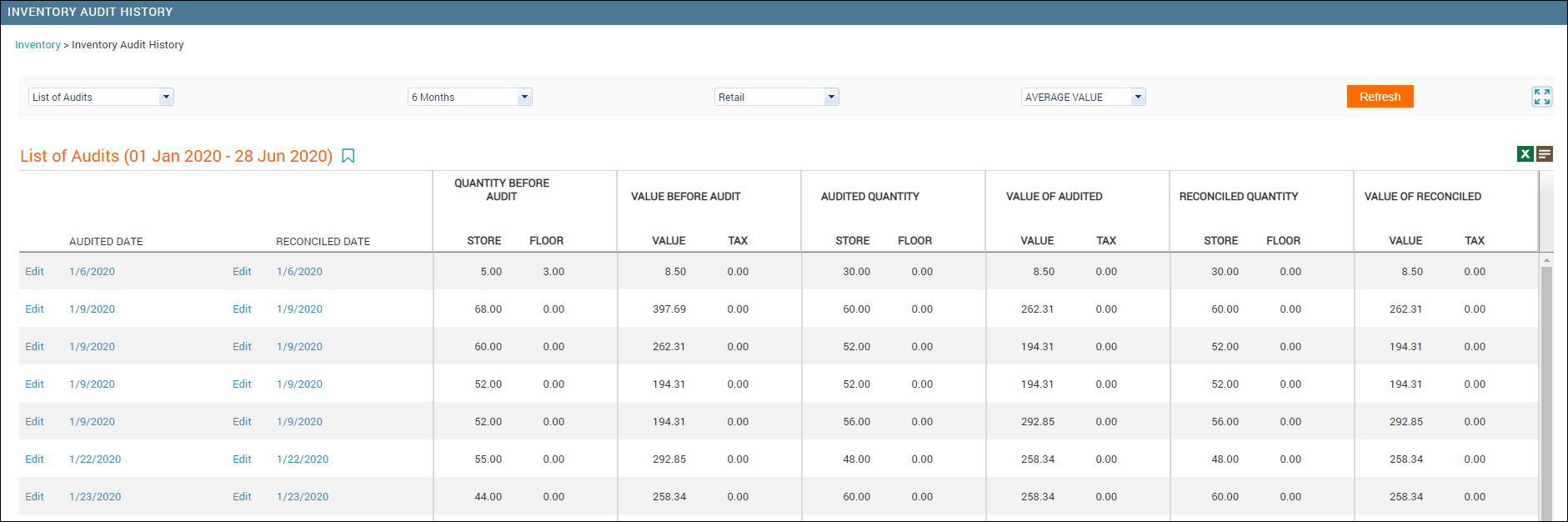

When audits are reviewed later, these notes appear in the Audit History Report, helping auditors understand why changes were made.

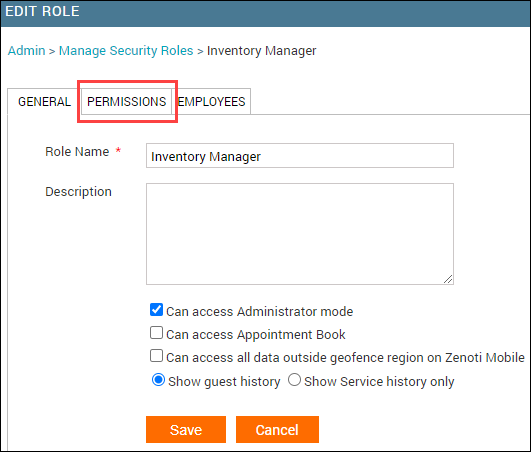

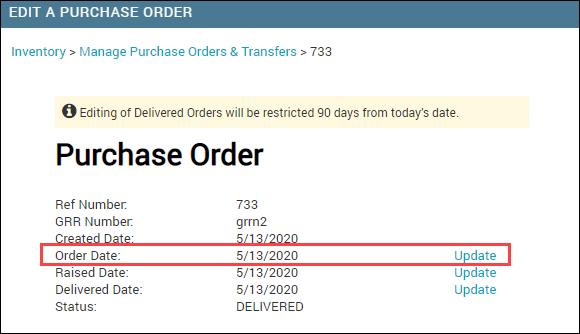

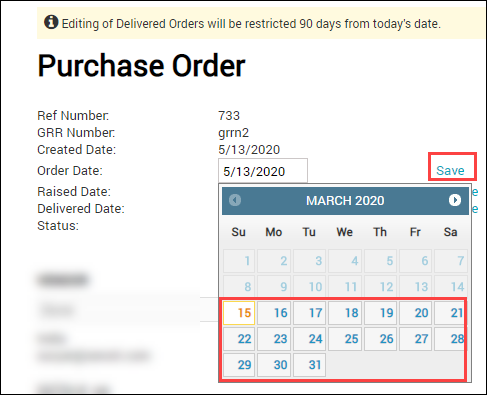

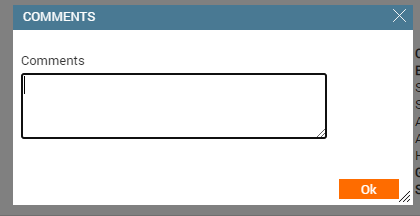

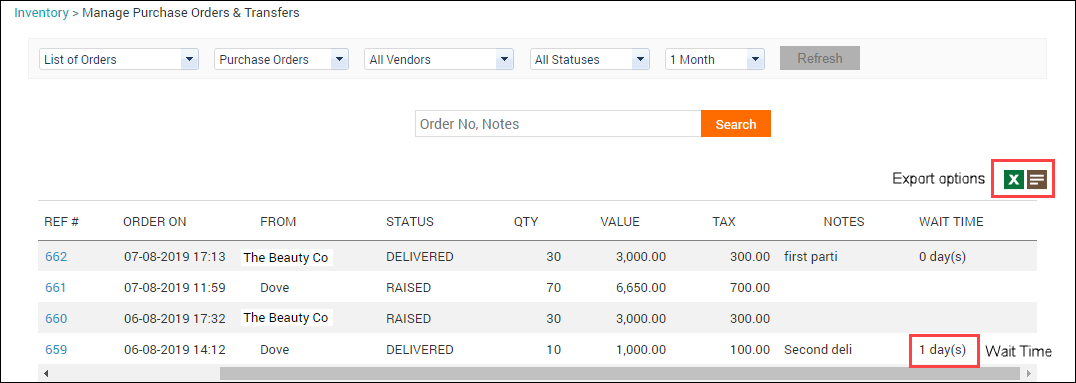

How can I manage purchase orders in Zenoti effectively?

Effectively managing purchase orders in Zenoti involves understanding the various steps, configurations, and limitations related to creating, updating, and troubleshooting purchase orders.

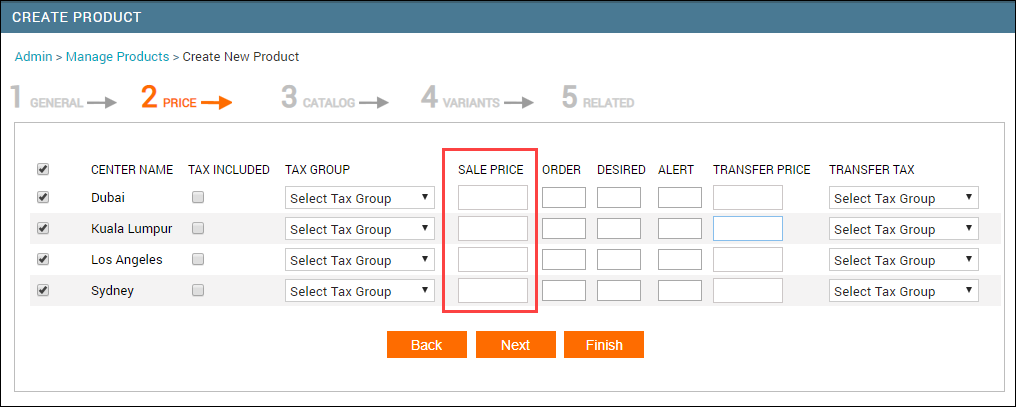

At the center level, navigate to Inventory > Orders > Raise a Purchase Order. Add vendor details and item quantities. Review the order and save it as a draft or raise it. Centers can be restricted from raising orders if your admin enables Prevent center from raising purchase orders.

Warehouse or corporate teams can raise orders created by centers. Enable the Raise_Order permission at the org level and restrict centers if needed. Review pending orders under Procurement > Orders and raise them after verification.

Open the raised order, enter received quantities, add shipment details, and save. Click Partial Delivery to update stock and generate delivery history. Price-difference prompts appear if enabled by admins.

Open the order, adjust received quantities, add delivery details, and click Full Delivery. Stock updates instantly, and the order status changes to Delivered. Excess quantities are allowed only when enabled by admins.

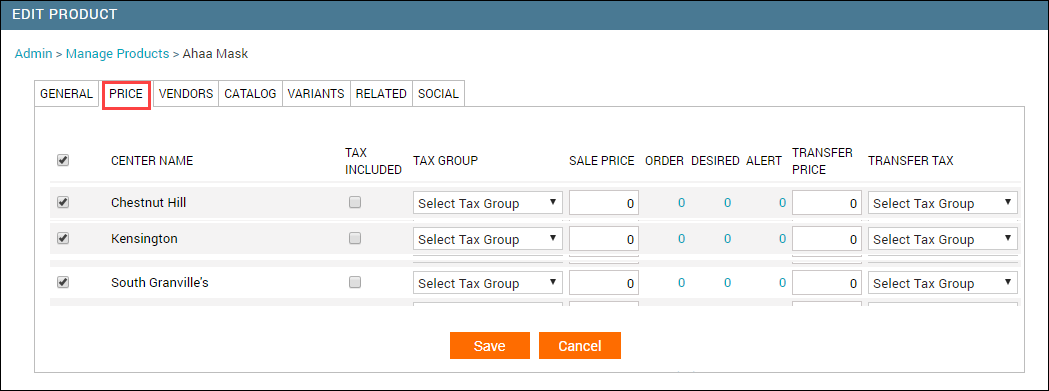

Define at least one tax type to create a purchase order.

Purchase orders can only be created at the center level, not the organization level. To distribute stock across locations, set one center as a vendor and use it to supply items to other centers.

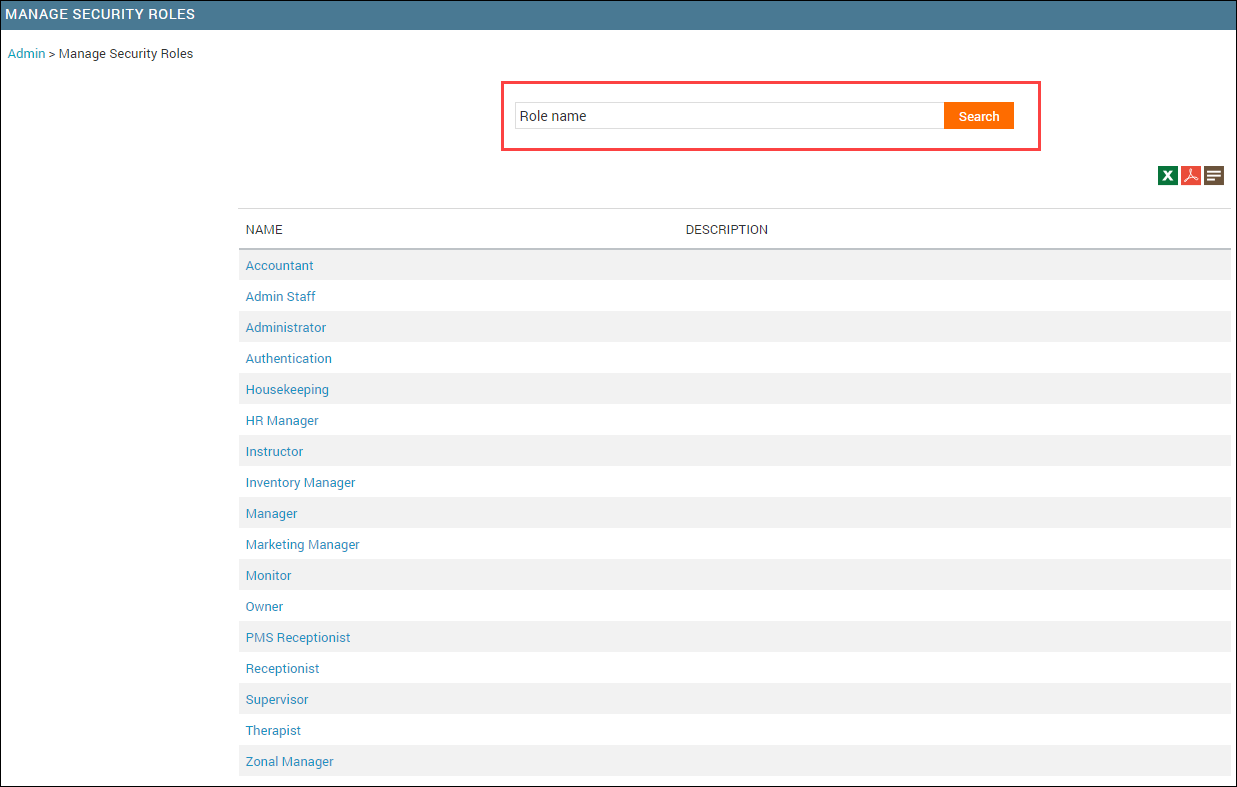

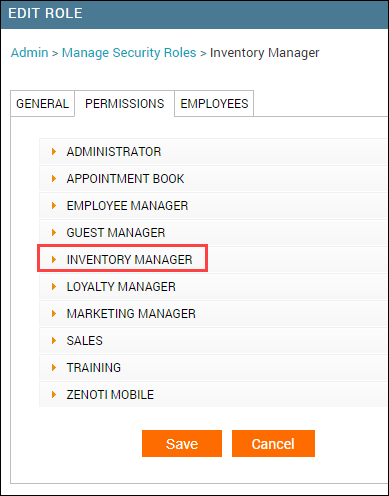

What are the dependent Inventory settings across Orders, Stock Actions, Essentials, and Audits in Zenoti?

Orders settings and their dependencies

Display products in the order added in inventory orders: This affects product ordering in Purchase Orders, Transfer Orders, and invoices in the Orders flow.

Restrict recipient center from editing transfer orders: Enable this if you want the destination center to only receive, not modify, the Transfer Order.

Restrict recipient center from editing price, discount, and tax fields after a transfer order is raised: This should be enabled together with the previous restriction for complete lock-down at destination.

Restrict delivery of transfer orders in the source center: When enabled, delivery is blocked and the dispatch workflow becomes mandatory for Transfer Orders.

Restrict partial deliveries for transfer order: This is most useful with dispatch flow, because it forces one complete delivery per Transfer Order.

Restrict partial deliveries for purchase order: Enable this when you want full deliveries only, especially for strict vendor reconciliation.

Allow delivered quantity to be more than ordered quantity in Purchase Order: Only enable if your process allows over-delivery, or your audits handle extra stock cleanly.

Allow delivered quantity to be more than ordered quantity in Transfer Order: Pair this with clear approval rules, because destination stock can exceed planned movement.

Consider raised purchase orders/transfer orders for calculating Auto PO/TO quantity: This depends on using Auto PO/TO alerts; it prevents double-ordering by counting raised quantities.

Enable multiple scans of barcodes for transfer and purchase orders: Works best when you maintain primary and secondary barcodes for the same product.

Show alert if required fields are missing when taking the order delivery: When enabled, these fields become mandatory before delivery can be completed.

Date of Shipment becomes mandatory for delivery completion.

Date of Delivery becomes mandatory for delivery completion.

Address of Delivery becomes mandatory for delivery completion.

Stock actions settings and their dependencies

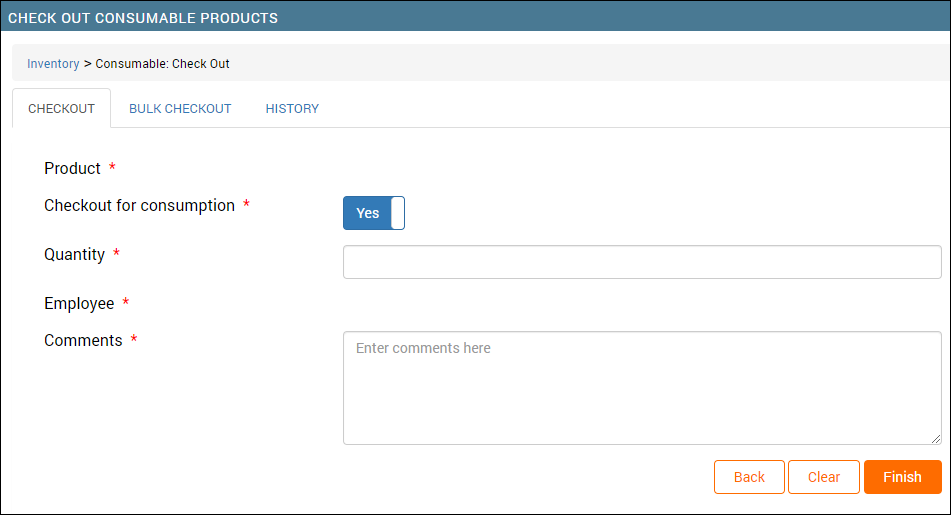

Allow product checkout, transfer and conversion when stock is not available: This controls negative stock behavior and impacts every checkout, transfer, and conversion action.

Enable auto checkouts from store to floor for product transfers: This only matters if you move items through Store and Floor locations during transfers.

Enable auto checkouts from store to floor for retail product sales: Use this if retail sales should always reduce Floor first without manual checkout.

Enable auto checkouts for consumable product consumption: This depends on consumables being tracked on Floor, so consumption can auto-checkout correctly.

Manual checkout for consumption when checking out from store to floor: Enable this if staff must choose a “consumption” reason during checkout, not just a default move.

Essentials settings and their dependencies

Enable product transfers between centers: If disabled, Transfer Order options disappear from Orders, even if other TO settings are enabled.

Enable product conversions: This unlocks the Conversion tab, and it also relies on negative stock setting if stock can dip.

Allow to restock returned products: This affects POS returns and invoice refunds, and should match your accounting policy.

Enforce approval for reconciliation for difference between expected and audited stock value: This unlocks the Approvals page and makes reconciliations require approval when deviation crosses a set limit.

Audit settings and their dependencies

Hide the option to use zero stock values for unaudited products under Product Audits: Enable this if zero stock audits must be prevented, especially in strict compliance environments.

Enable partial audit of products: This is irreversible after enabling, and it hides older V1 inventory reports permanently.